Perovskite Thin Film Lab

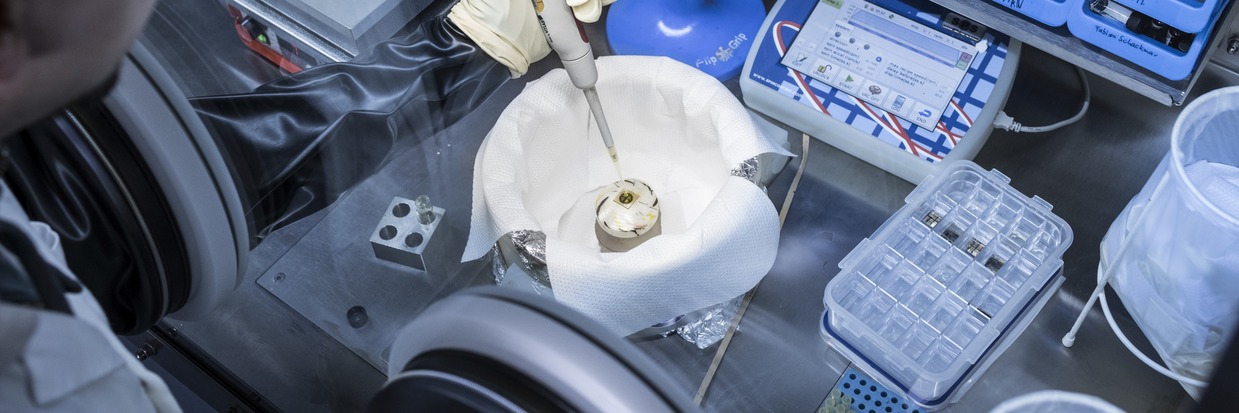

The perovskite thin film lab is equipped with a large variety of fabrication and characterization methods. All methods are operated in or accessible from inert atmosphere, allowing for processing of perovskite optoelectronic devices in high controlled conditions. The lab enables the processing of high efficiency perovskite solar cells and perovskite-based tandem solar cells.

- Several Gloveboxes equipped with spin coaters.

- Electron beam evaporation system for deposition of oxides, metals etc.

- (Multipocket, process gases O2).

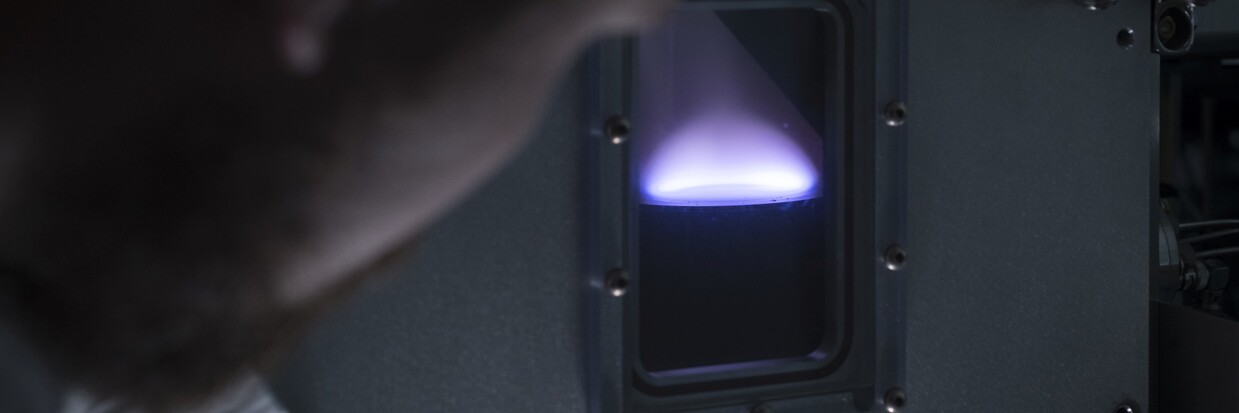

- Sputter system for the deposition of transparent conductive oxides and oxides.

- Thermal evaporators for metals and organic materials.

- Solar Simulator in inert atmosphere.

- External quantum efficiency setup and spectrophotometry setup in inert atmosphere.

- Fume hoods equipped with spin coater and hot plates

- Basic lab equipment (plasma cleaner, profilometer, etc.)

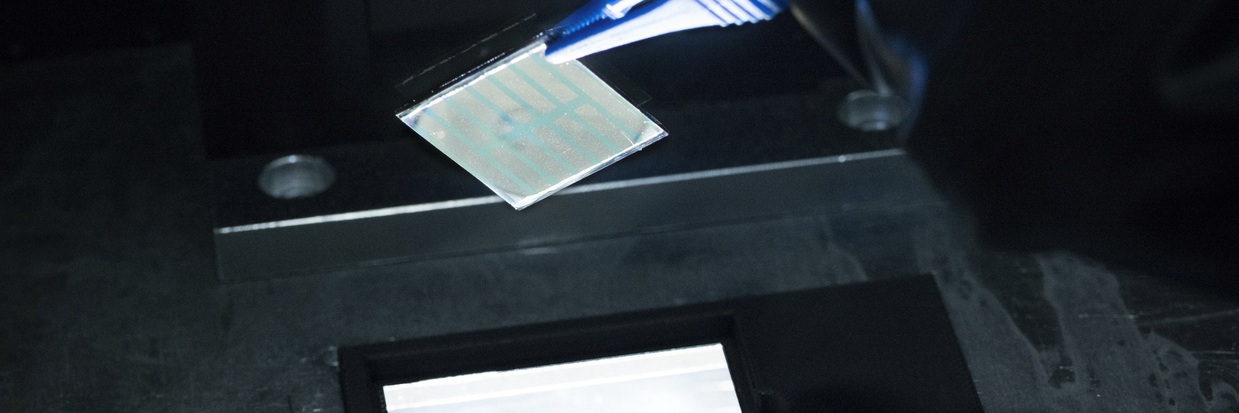

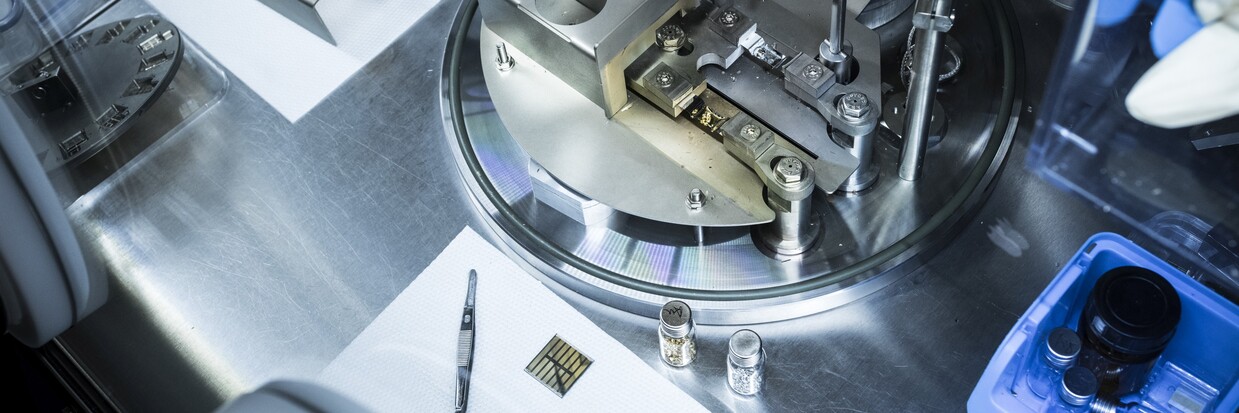

Solar Module Fabrication Platform

This platform allows processing perovskite thin film solar modules in inert atmosphere up to areas of 20 x 20 cm²:

- Laser patterning system in inert atmosphere.

- Light-beam-induced current (LBIC) mapping setup.

- Photoluminescence (PL) and electroluminescence (EL) mapping setup.

- White light interferometry.

In-Situ Characterization Platform of Large Area Solution-Processed Perovskite Thin Films

The platform combines a variety of in-situ characterization techniques with scalable solution-based deposition of perovskite thin films. The target is to understand better the complex dynamics during the formation of perovskite thin-films.

- Slot-die and blade coating (up to 20 cm x 20 cm)

- Impact jet dryers, nozzle dryers, near-infrared (NIR) dryers

- In-situ optical spectroscopy by reflection spectroscopy, (transient) photoluminescence and Raman spectroscopy

- In-situ imaging by white light interferometry and photoluminescence

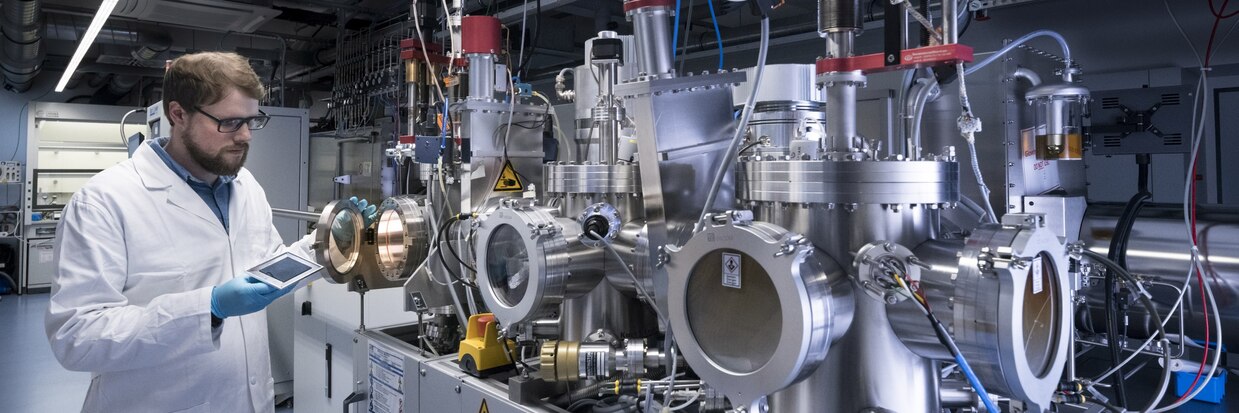

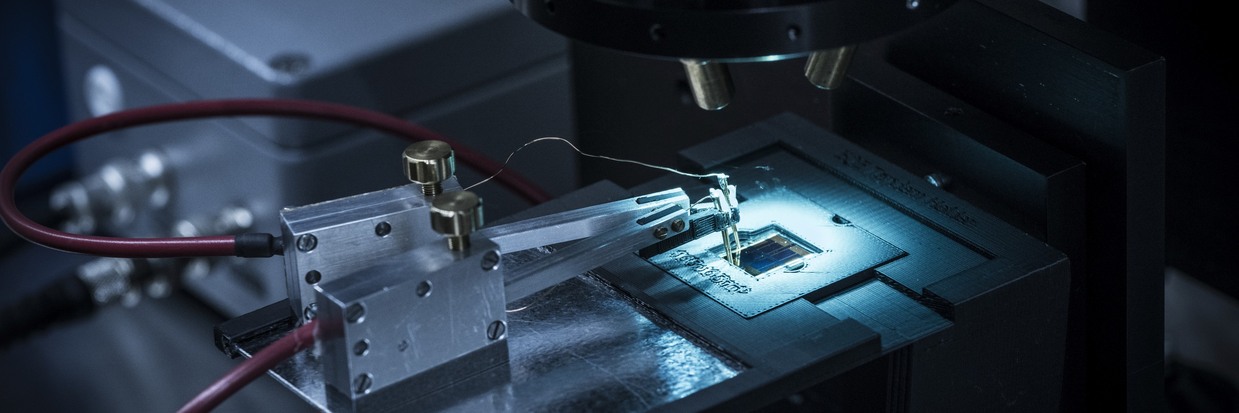

Upscaling of Evaporated Perovskite Photovoltaics

Our labs are equipped with dedicated evaporation systems that enable co-evaporation of complex compositions of perovskite semiconductors (e.g. multi-cation and wide-bandgap candidates) and deposition on areas up to 6 inches.

- Perovskite evaporation system (5 sources, cold trap)

- Thermal evaporation system (organic and inorganic charge transport layers, electrodes)

- Sample handling fully in inert atmosphere

- Small secondary perovskite evaporation system (2 sources)

Stability Test Setup

In order to examine the durability and stability of the materials and perovskite devices, we build up dedicated test setups that comply with the most relevant international stability protocols.

- Environmental test chamber (relative humidity: 15-85%, light intensity: 0.1-1sun, temperature: 10-85°C, simultaneous MPP-tracking of 24 samples)

- Stability tests in inert atmosphere (light intensity: 0.1-1sun, temperature: 10-85°C, simultaneous MPP-tracking of 64 samples)