Neuartige Materialien für Perowskit-Photovoltaik

Die Perowskit-Dünnschicht-Photovoltaik verspricht eine drastische Senkung der Kosten der nächsten Generation von Photovoltaikanlagen. Während die Perowskit-Photovoltaik in den letzten zehn Jahren eine stark verbesserte Effizienz bei der Energieumwandlung gezeigt hat, hängen die Zukunftsaussichten dieser Technologie von einem Durchbruch bei der Entwicklung stabiler und langlebiger Perowskit-Materialien von hoher optoelektronischer Qualität ab. Außerdem sind bleifreie Alternativen erwünscht, um die Akzeptanz dieser Technologie zu erleichtern. Angesichts der unzähligen Zusammensetzungen von Perowskit-Halbleitern ist ein wissensbasierter Ansatz für das Materialdesign erforderlich. Aus diesem Grund untersucht unser Team nicht nur eine Vielzahl von Perowskit-Halbleitern (z. B. "Multi-Kationen", "anorganisch", "bleifrei", "zweidimensional (2D)"), sondern beschäftigt sich auch intensiv mit der Analyse optoelektronischer Eigenschaften wie der Ladungsträgerdynamik [1], dem Photonen-Recycling [2] [3], der Variation der Zusammensetzung [4] [5] und der Morphologie der Dünnschicht [6].

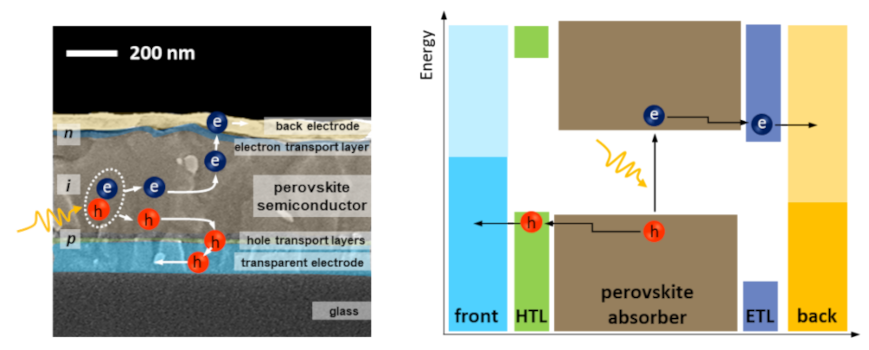

Abbildung 1: Rasterelektronenbild einer Dünnschicht-Perowskit-Solarzelle im Querschnitt und zugehöriges Energiediagramm.

Zweidimensionale (2D) Perowskit-Halbleiter und 2D/3D-Perowskit-Heterostrukturen:

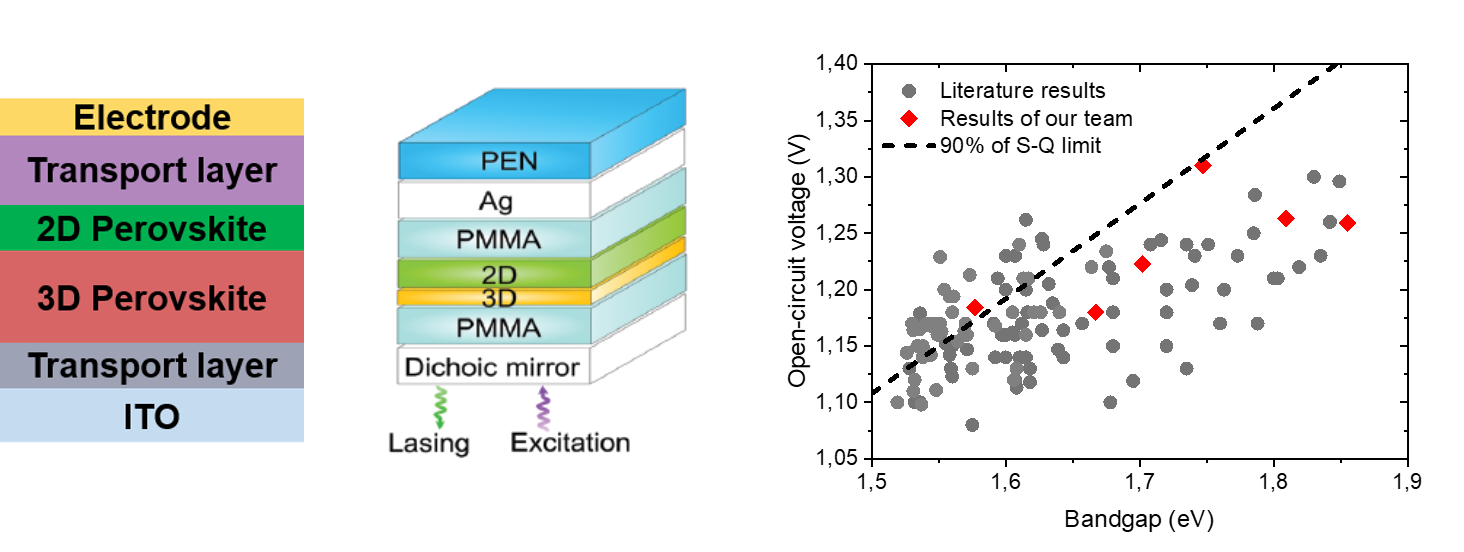

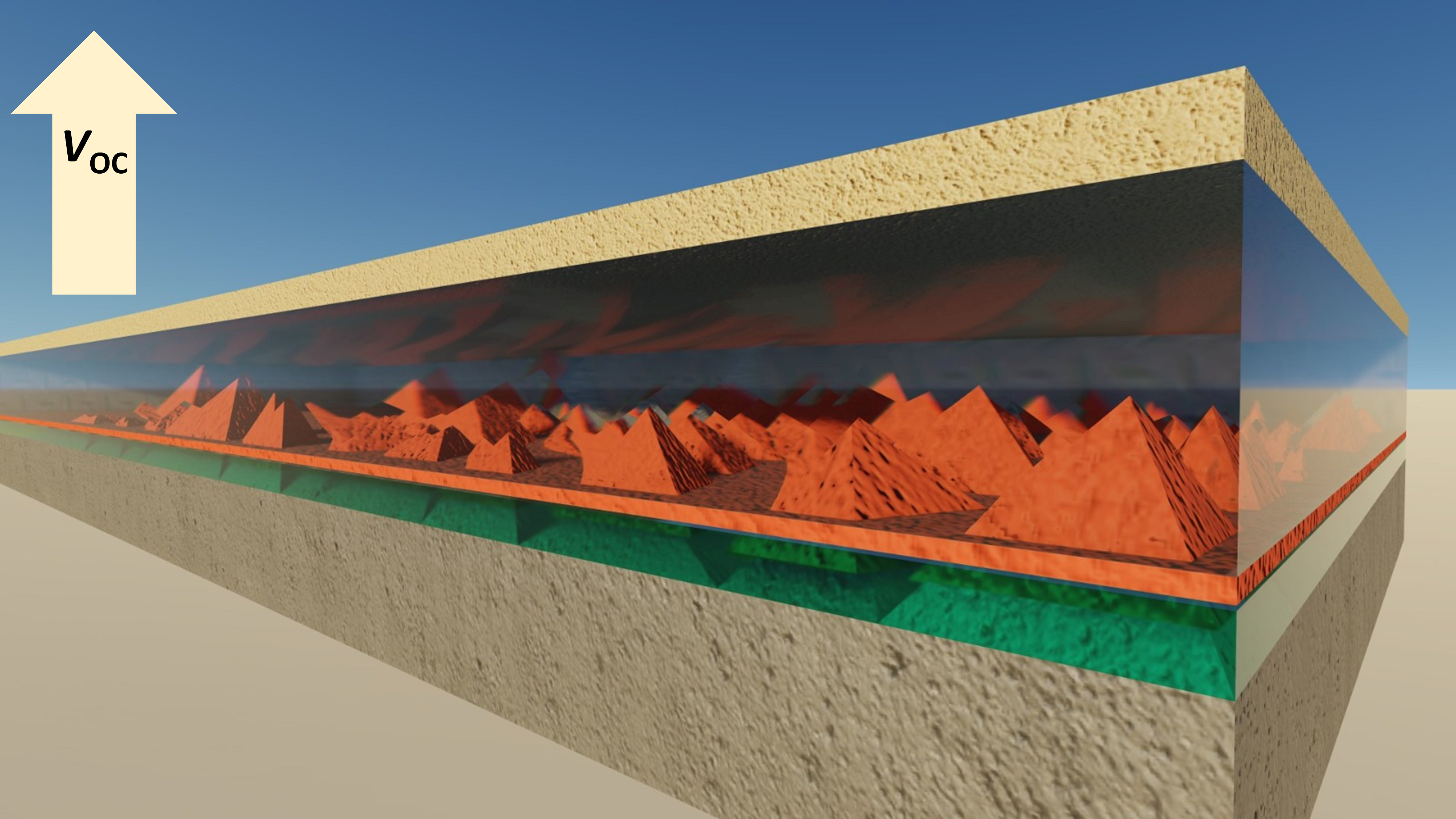

Nicht nur dreidimensionale (3D) Perowskit-Halbleiter, sondern auch ihre zweidimensionalen (2D) Analoga weisen hervorragende optoelektronische Eigenschaften auf. 2D-Perowskit-Halbleiter haben eine vielversprechende Stabilität gegenüber Umwelteinflüssen gezeigt und dienen als Plattform für die Realisierung bleifreier Alternativen sowie von Leuchtdioden und Lasern auf Perowskit-Basis. Da jedoch die 2D-Struktur einen effizienten Ladungstransport erschwert, zeigen reine 2D-Perowskit-Solarzellen typischerweise eine begrenzte Geräteperformance. Durch den Einsatz voluminöser Alkylammoniumkationen an der Oberfläche eines 3D-Perowskitfilms entsteht eine sogenannte 2D/3D-Heterostruktur (siehe Abb. 1). Unser Team hat kürzlich gezeigt, dass solche Strukturen (i) nichtstrahlende Rekombinationsverluste in Perowskit-Solarzellen stark reduzieren [7], [8], [9] und (ii) den Ladungstransfer im angeregten Zustand in Perowskit-basierten Lasern verbessern können [10]. Dies führt zu erstaunlich hohen Leerlaufspannungen in Solarzellen über einen weiten Bereich von Bandlücken (siehe Abb. 2) und reduziert die Schwelle der verstärkten spontanen Emission (ASE) in Lasern im Vergleich zu den 3D-Analoga ohne Heterostruktur.

Abbildung 2: Schema einer 2D/3D-Heterostruktur in einer Perowskit-Solarzelle (links) und einem Perowskit-basierten Laser (Mitte). Leerlaufspannung von Perowskit-Solarzellen für verschiedene Bandlücken (rechts). Die grauen Punkte stellen literarische Ergebnisse dar, während die rote Raute Ergebnisse unseres Teams zeigt. Die gestrichelte Linie repräsentiert 90 % der Shockley-Queisser-Grenze.

Stabile und hochwertige Perowskit-Halbleiter durch Kompositionstechnik:

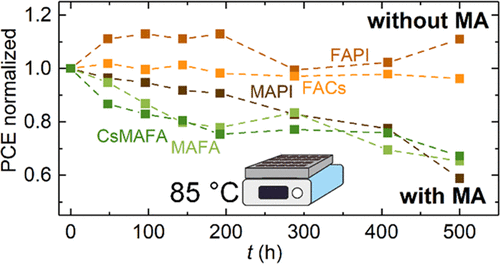

Das Compositional Engineering von defekttoleranten Perowskit-Halbleitern beschreibt die Variation der organischen und anorganischen Komponenten in der Kristallstruktur. Die Fortschritte auf diesem Gebiet in den letzten Jahren haben zu Multi-Kationen-Perowskit-Halbleitern geführt, die eine verbesserte, aber noch nicht ausreichende Stabilität und Energieumwandlungseffizienz aufweisen. Um die Stabilität weiter zu verbessern, erforschen wir die zugrunde liegenden Mechanismen der licht- [11] [12], temperatur- [13] [14] und feuchtigkeitsinduzierten Degradation. Wir entwickeln Richtlinien für das Materialdesign und die Bauelementearchitektur im Hinblick auf die Zusammensetzung von Multikation-Perowskiten [5], Passivierungsschichten [15] und Ladungstransportschichten [16] [17].

Abbildung 3: Auswirkung der thermischen Belastung auf Perowskit-Dünnschichten im Hinblick auf ihre Leistung in Perowskit-Solarzellen.

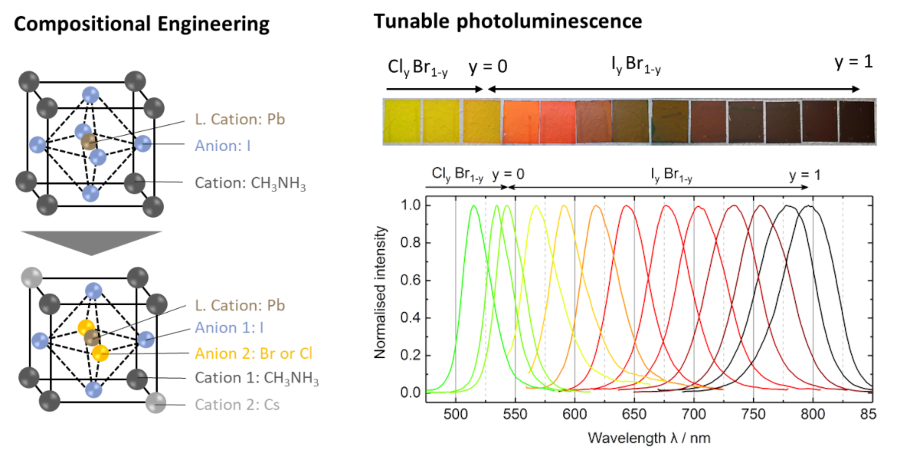

Maßgeschneiderte Bandlücken von Perowskit-Halbleitern:

Maßgeschneiderte Bandlücken sind von größter Bedeutung für die Realisierung hocheffizienter Tandem-Photovoltaik auf Perowskit-Basis. Während die optimale Bandlücke für eine Perowskit-Top-Solarzelle in der Tandem-Architektur mit kristallinem Silizium (c-Si) oder Kupfer-Indium-Gallium-Selenid (CIGS)-Solarzellen 1,7-1,8 eV beträgt, liegt die optimale Bandlücke der Perowskit-Boden-Solarzelle in reinen Perowskit-Tandem-Solarzellen unter 1,3 eV. Durch Anwendung einer neuartigen Passivierungsstrategie konnten wir eine hervorragende Leistung von Perowskit-Solarzellen mit breiter Bandlücke (~1,7 eV) nachweisen. Darüber hinaus erforschen wir neue Wege, um die Kristallisation von Perowskit-Dünnschichten mit niedriger Bandlücke (~1,26 eV) für effiziente Vollperowskit-Tandemsolarzellen zu kontrollieren [18] [19] [20].

Abbildung 4: Die Bandlücke der Perowskite lässt sich durch Zusammensetzungsmechanismen einstellen.

Texturierte Oberflächen:

Die Verarbeitung von Perowskit-Solarzellen über mikrometergroße pyramidale Texturen ist ein aktuelles Forschungsthema. Wir präsentieren eine umfassende Studie über die potenziellen Gründe für die verschiedenen Spannungsverluste, die mit der Verarbeitung von Perowskit-Dünnschichten auf texturierten Oberflächen einhergehen, mittels morphologischer, mikrostruktureller und kompositorischer Analysen. Wir untersuchen mehrere Strategien zur Verringerung der Spannungsverluste, wie z. B. Oberflächenpassivierung, Grenzflächentechnik, Verarbeitungsparameter, Konzentration und Stöchiometrie der Perowskit-Vorläufer und Lösungsmitteltechnik.

Abbildung 5: Illustration einer Perowskit-Dünnschicht, die über eine texturierte Oberfläche verarbeitet wurde.

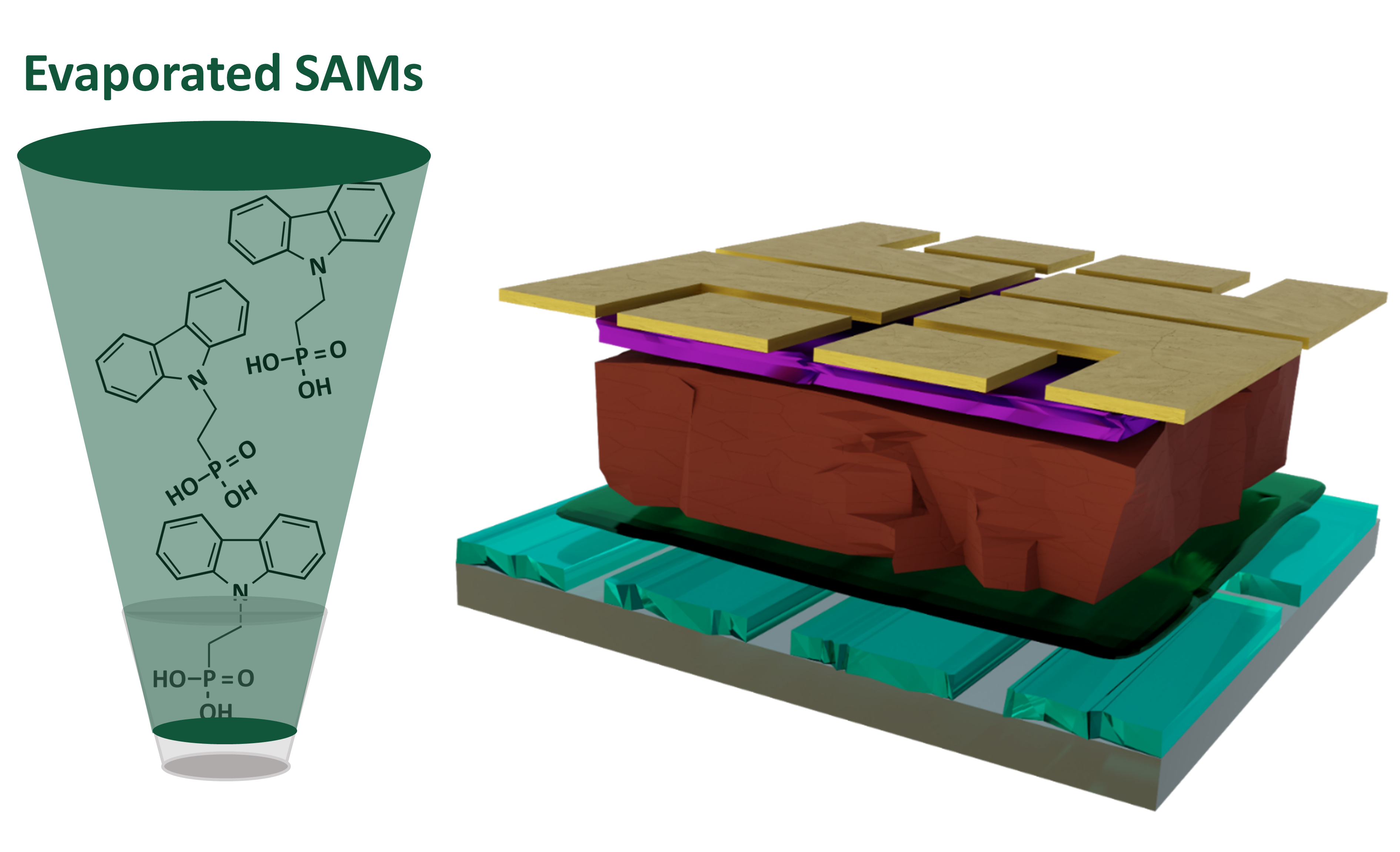

Aufgedampfte SAMs:

Die Relevanz selbstorganisierender Monolagen als Lochtransportschichten (SAM-HTLs) zeigt sich darin, dass viele hocheffiziente PSCs mit einem Übergang und monolithische Tandems auf Perowskitbasis, PACz-Derivate (d. h. 2PACz, MeO-2PACz und Me-4PACz) verwenden. Bislang wurden diese Materialien ausschließlich mit lösungsbasierten Methoden abgeschieden, was ihre Vielseitigkeit und Prozessflexibilität einschränkt. Um diese Herausforderung zu überwinden, präsentieren wir die erste vakuumbasierte Verdampfung von gängigen SAM-HTLs.

Abbildung 6: Illustration der vakuumbasierten Verdampfung gängiger SAM-HTLs.