Ecofriendly Fabrication of Organic Solar Cells

Organic bulk-heterojunction solar cells are on the cusp of commercialization. Printing and coating techniques are widely considered enablers of low-cost solar module fabrication with excellent carbon footprints. For the transfer of lab-scale processes to an environmentally friendly and sustainable industrial large-scale fabrication of polymer solar cells by printing, non-halogenated solvents and processing additives are mandatory prerequisites. As the choice of solvents is pivotal to the complex formation of the bulk-heterojunction and hence to the device performance, both academia and the solar industry have fostered strong research on ”green” device processing in order to advance the market-readiness of organic solar modules.

|

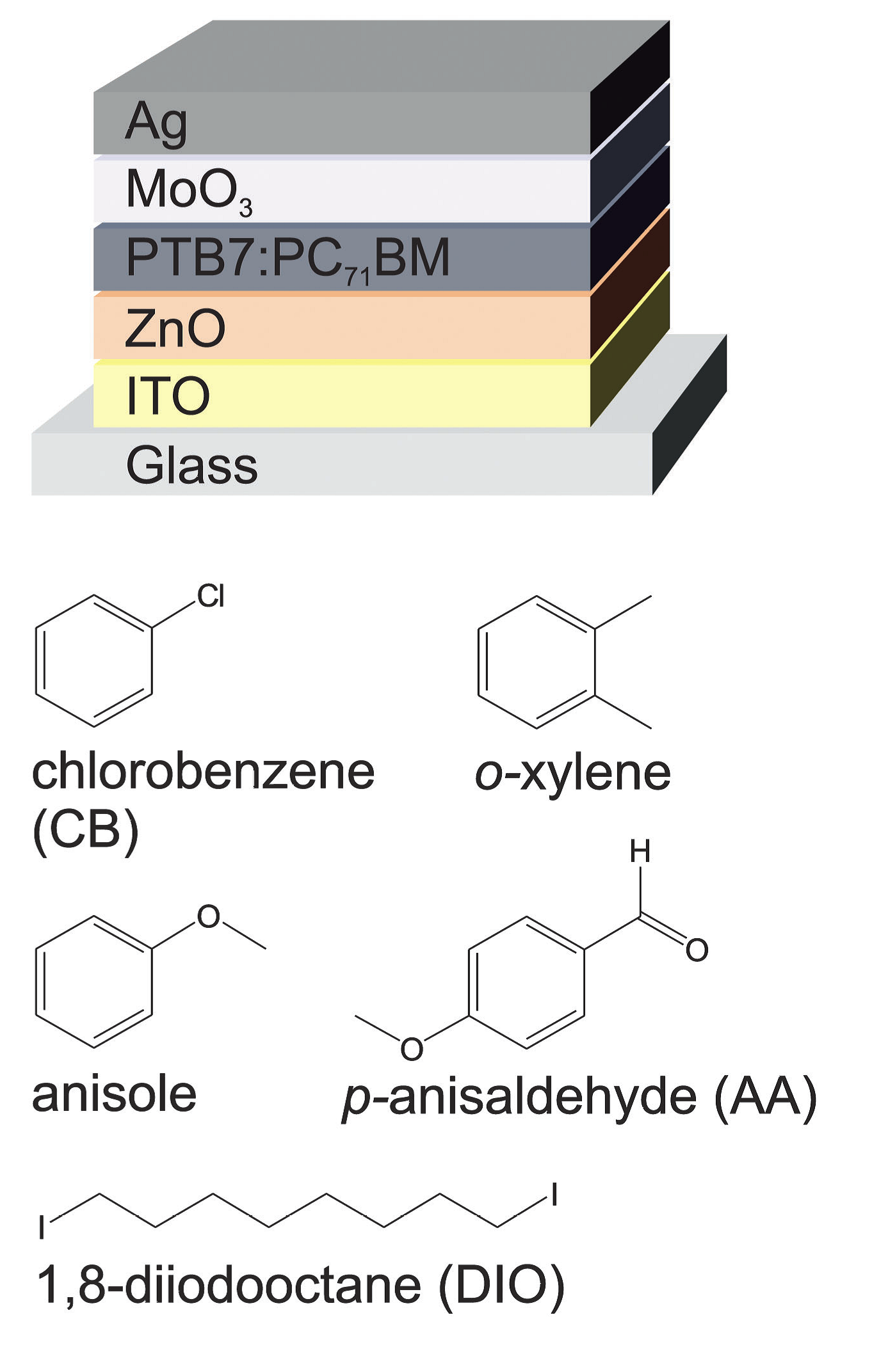

In order to modify common deposition processes towards eco-compatible device fabrication, several high performance polymer:fullerene bulk-heterojunction photo-active layers were deposited from the non-halogenated solvents o-xylene or anisole in combination with the eco-compatible additive p-anisaldehyde. The respective solar cells yield excellent power conversion efficiencies beyond 10%, outperforming reference devices deposited from the commonly used halogenated chlorobenzene/1,8-diiodooctane solvent/additive combination. The additive p-anisaldehyde improves film formation, enhances polymer order, reduces fullerene agglomeration and shows high volatility, thereby positively affecting layer deposition, improving charge carrier extraction and reducing drying time, the latter being crucial for future large area roll-to-roll device fabrication. |

|

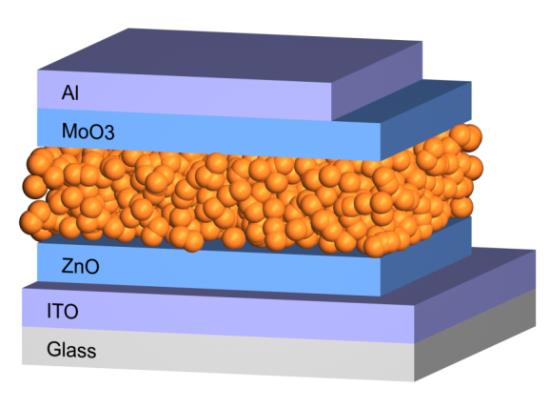

Ultimately, the fabrication of organic solar cells should target the deposition from environmentally friendly agents such as water or alcohols. As organic semiconductors usually do not dissolve in polar solvents, we investigated their disperson in non-solvents. From alcoholic nanoparticle dispersions we have fabricated P3HT:ICBA solar cells with a power conversion efficiency of 4-5%, almost matching the performance of solar cells that were fabricated from chlorinated solvents. Thermal treatment of the active layer after deposition enabled a more intimate contact of the nanoparticles and hence better charge carrier extraction. The deposition of photo-active layers from alcohol can pave the way to a low-cost and fully eco-friendly, large-scale fabrication of organic solar cells in the future, where non-toxic fabrication processes are important in order to avoid costly safety measures, and may well be adapted for other organic optoelectronic devices. |

Further reading:

- S. Sankaran et al., Eco-friendly fabrication of polymer-fullerene bulk-heterojunctions from organic nanoparticle dispersions by doctor blading and ink-jet printing, Org. Electronics, 2016, 28, 118-122, DOI: 10.1016/j.orgel.2015.10.011.

- C. Sprau et al., Highly Efficient Polymer Solar Cells Cast from Xylene:Anisaldehyde Solution, Energy & Environ. Sci., 2015, 8, 2744-2752, DOI: 10.1039/C5EE01917F.

- S. Gärtner et al., Eco-friendly fabrication of 4% efficient organic solar cells from surfactant-free P3HT:ICBA nanoparticle dispersions, Adv. Mater., 2014, 26, 6653–6657, DOI: 10.1002/adma.201402360.