Organic Solar Modules

In recent years organic solar cells have been reported to yield efficiencies exceeding 10%. However, these efficiencies were achieved on small substrates and under laboratory conditions. Inkjet printing, slot-die coating or spray coating are feasible upscaling methods that enable the production of low-cost solar modules with excellent energy payback time and low carbon footprints. In order to manufacture these modules with lab scale power conversion efficiencies, monolithic serial interconnection of organic solar cells with negligible inactive areas, i.e., high geometric fill factors, are needed. Different scribing methods using mechanical, chemical or laser technologies have been demonstrated. Laser scribing methods offer the advantage of achieving a high geometric fill factor while selectively structuring the different layers of the solar module.

|

Mechanically flexible, all-solution processed, indium tin oxide-free organic solar cells on polyethylene terephthalate (PET) substrates yield power conversion efficiencies up to 4.8%. The mechanical properties of the devices are dictated by the electrodes from either metal-organic silver inks or a combination of the conductive transparent polymer poly(3,4-ethylenedioxythiophene):poly(4-styrenesulfonate) and silver nanowires. Both electrodes can sustain high tensile strains. The influence of mechanical strain on the solar cell performance was experimentally studied in situ by measuring the current density-voltage curves of elongated samples under illumination. At a lateral strain of 14%, which translates into a bending radius of about 1 mm, we still observed 90% of the initial device power output. This is a significant improvement over solar cells comprising conventional indium tin oxide electrodes on PET. |

|

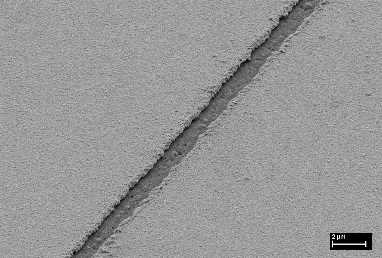

When moving forward from lab-scale device engineering to larger scale solar modules, lateral structuring of the devices becomes important in order to reduce the device current and hence the ohmic losses. Ultrashort-pulse lasers offer many opportunities to selectively structure the various layers of an organic solar module. We successfully structured an indium tin oxide electrode on top of glass and a silver layer on top of polyethylene terephthalate (PET) substrates using a 90 fs ultra-short pulse amplifier system with wavelengths in the visible. The scribed lines on ITO show widths of less than 5 µm with edges lower than 30 nm without visible damage to the glass surface. Likewise, the ablation of silver shows widths of less than 2 µm with edges of less than 150 nm. The low edges prevent the risk of shunt formation between the top and bottom electrode. |

|

Using a combination of mechanical and laser scribing techniques, we fabricated organic solar modules with photo-active areas exceeding 20 cm2 in a sheet-to-sheet process on rigid substrates. or a roll-to-roll compatible process on mechanically flexible substrates. By employing our know-how of evaporated and solution processed electrode systems as well as organic absorbers, we built semi-transparent and opaque solar modules, optimized for various applications. The average visible transparency and the power conversion efficiencies can be tuned in a broad range to match the application’s requirements. |

|

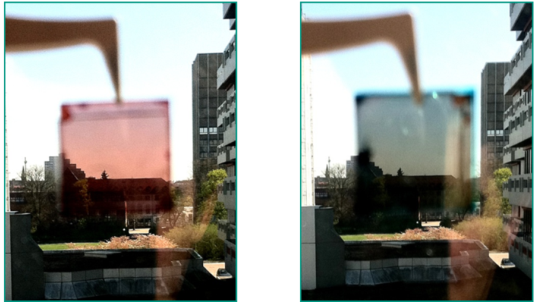

Consumer and lifestyle applications greatly benefit from the multitude of color options provided by organic absorbers. Especially semi-transparent solar cells open up new avenues for integration in, e.g., windows, overhead glazing and blinds. However, window integration demands a color neutral perception of organic solar modules and transmitted light should only be attenuated without spectral changes. We achieved these goals by careful design of solar cell architectures, utilizing the interplay of thin-film interferences of all functional layers and the selection of a suitable organic photoactive layer, without compromising the power conversion efficiency of the solar cells. Additionally, organic absorbers without intrinsically beneficial absorption profiles can be tuned towards color neutrality by integration of a spectrally complementary absorbing dye into a solution processed electrode. |

Further reading:

- J. Czolk et al., Mechanically Flexible, Semi-Transparent Organic Solar Cells Doctor Bladed from Non-Halogenated Solvents, Adv. Mater. Technol., 2016, 1600184, DOI:10.1002/admt.201600184.

- F. Nickel et al., Mechanically robust, ITO-free, 4.8% efficient, all-solution processed organic solar cells on flexible PET foil, Sol. Energy Mater. Sol. Cells, 2014, 130, 317, DOI: 10.1016/j.solmat.2014.07.005.

- J. Czolk et al., Inverted Semi-transparent Polymer Solar Cells with Transparency Color Rendering Indices approaching 100, Adv. Energy Mater., 2013, 3, 386, DOI: 10.1002/aenm.201200532.

- A. Colsmann et al., Efficient Semi-Transparent Organic Solar Cells with Good Transparency Color Perception and Rendering Properties, Adv. Energy Mater., 2011, 1, 599, DOI: 10.1002/aenm.201000089.